QUALITY

We pride ourselves on EKG's strict quality control, and perfect interpretation of customer needs.

-

Raw Material Inspection

Our dedicated professionals conduct rigorous testing on each batch of raw materials, examining their physical properties, chemical composition, hygiene indicators, and more, to ensure they comply with production requirements and industry standards. Furthermore, we have established a raw material traceability system that records information such as the source, inspection reports, and usage batches for each batch of raw materials, facilitating problem tracking and resolution.

-

Production Process Control

We will develop detailed production process flowcharts and work instructions to ensure standardization and regularization of the production process. Throughout the production process, we will identify and monitor key control points such as temperature, pressure, time, and other parameters to guarantee the stability of product quality. Advanced online monitoring equipment is employed to monitor production data in real-time, enabling the timely detection and correction of abnormal situations.

-

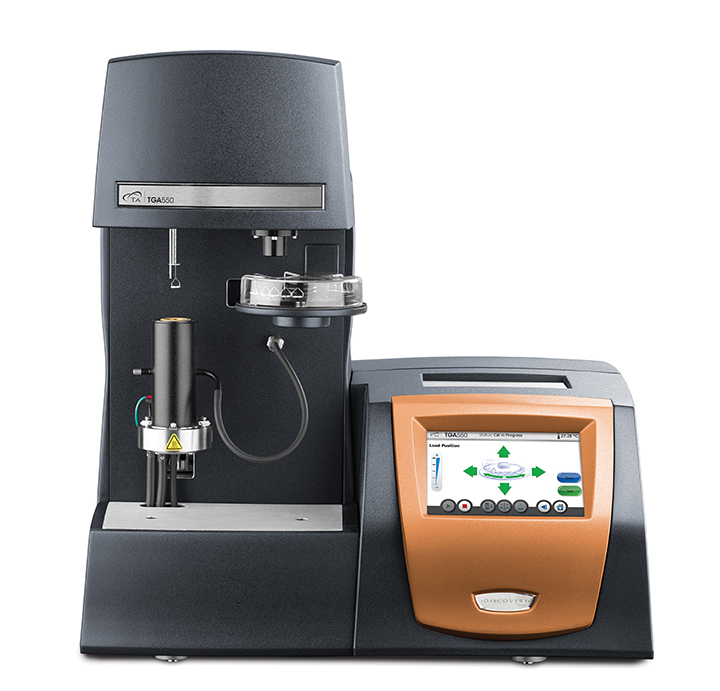

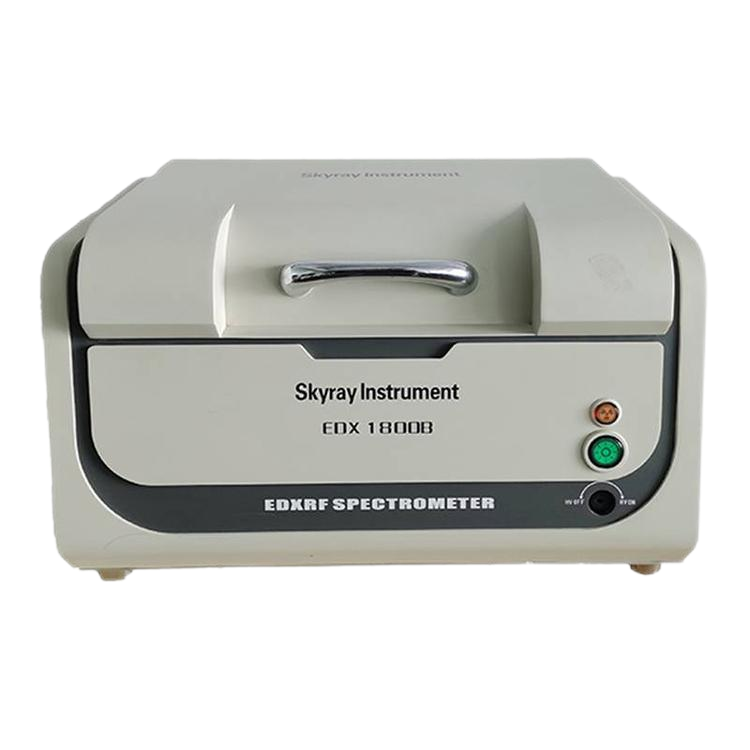

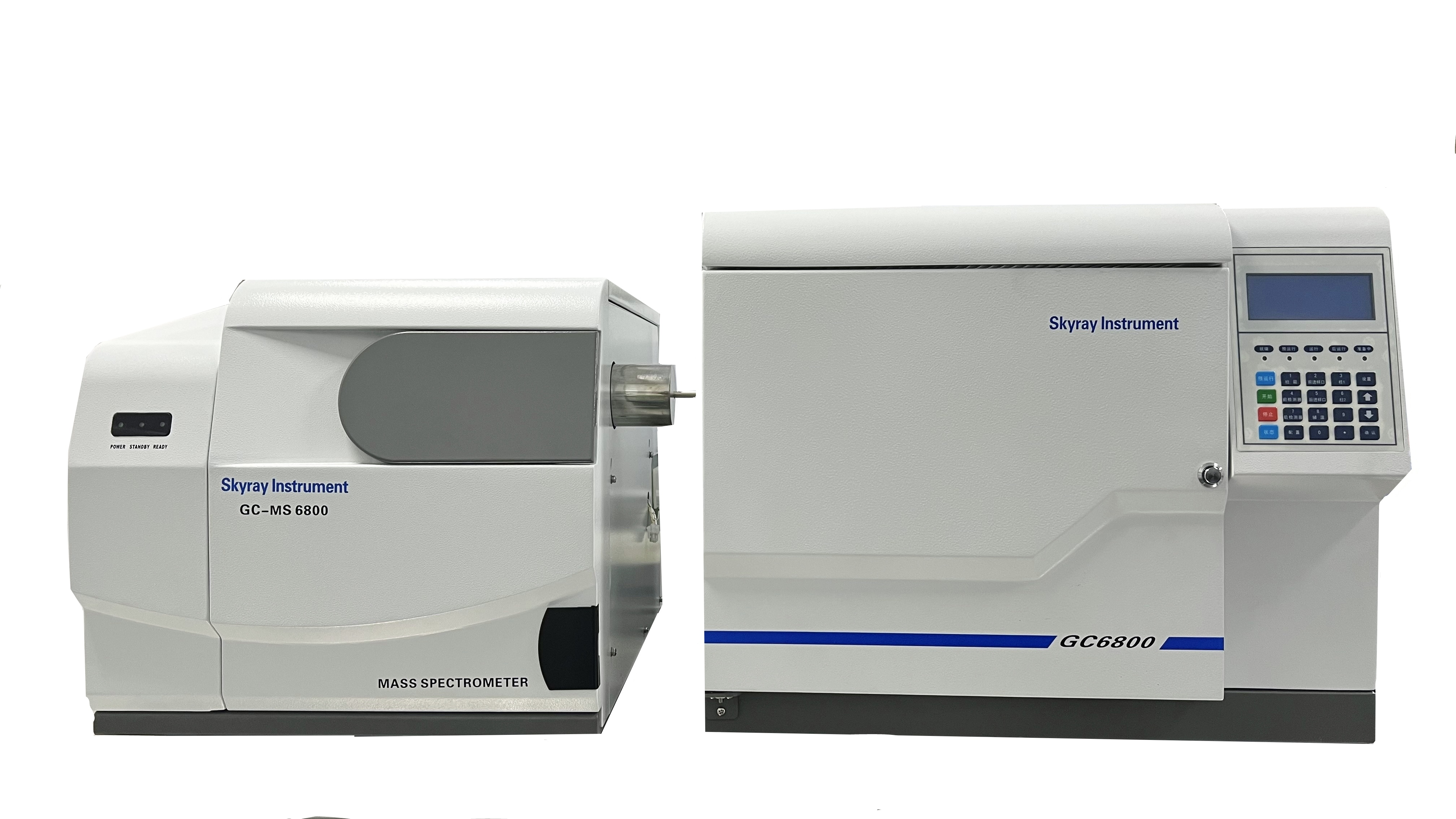

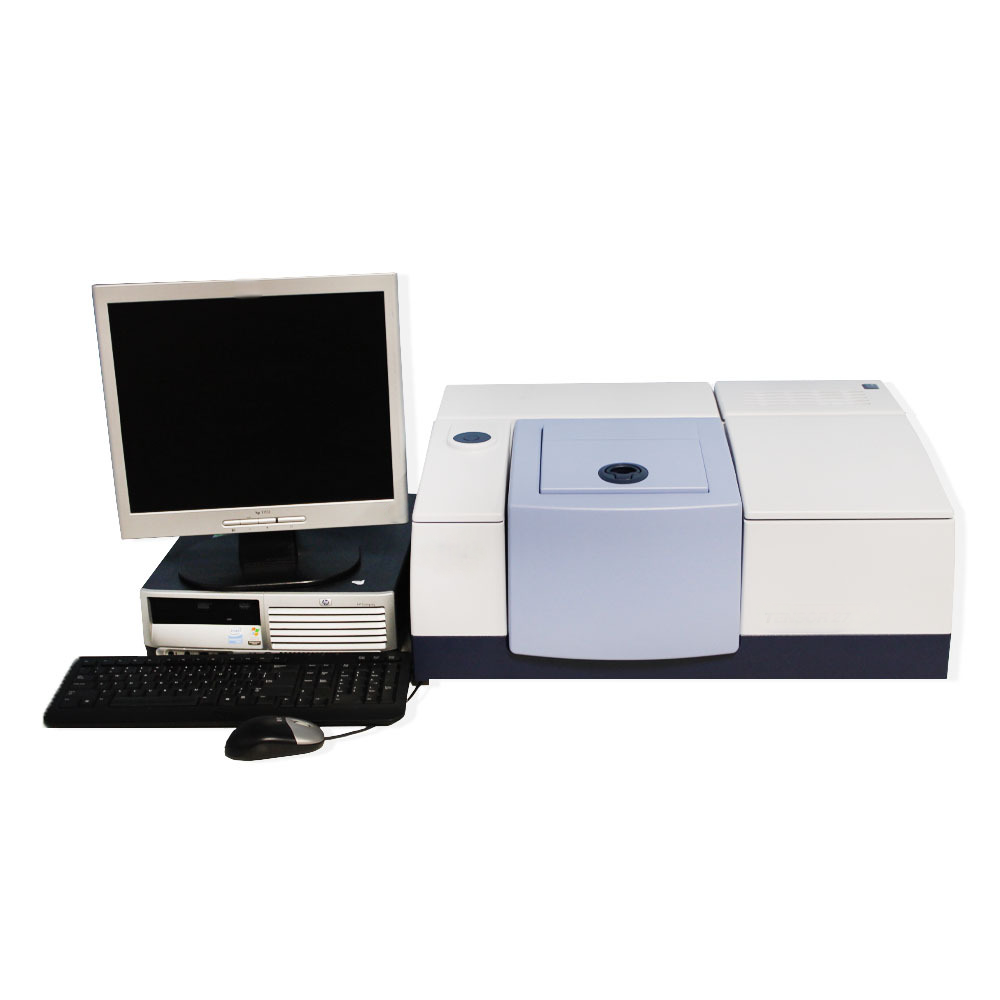

Product Inspection and Testing

Our factory is equipped with an independent laboratory, which conducts comprehensive inspections on randomly sampled finished products after production, encompassing aspects such as appearance, dimensions, performance, and more, to ensure that the products meet both design specifications and customer requirements.

-

MES Quality Tracking System

The MES system automatically collects real-time data from the production floor by integrating various sensors, automation equipment, and more. This data encompasses production parameters, equipment status, raw material information, and so on, providing a wealth of data sources for quality control. Through real-time data analysis, we can promptly identify abnormalities in the production process and take effective measures to rectify them, thereby ensuring the stability of product quality.

Qualification

Dongguan Thermoplastic Elastomer Engineering Technology Research Center

High-tech Enterprise

Specialized, Sophisticated, Innovative, and New Small and Medium-sized Enterpris